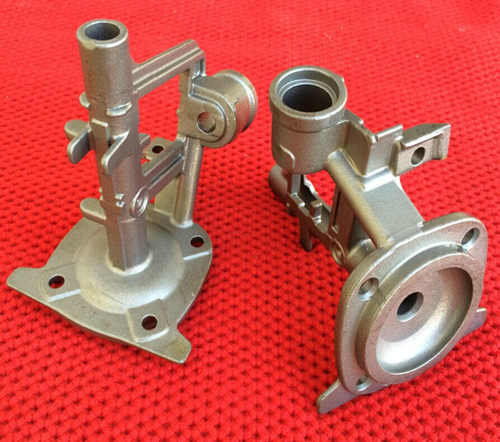

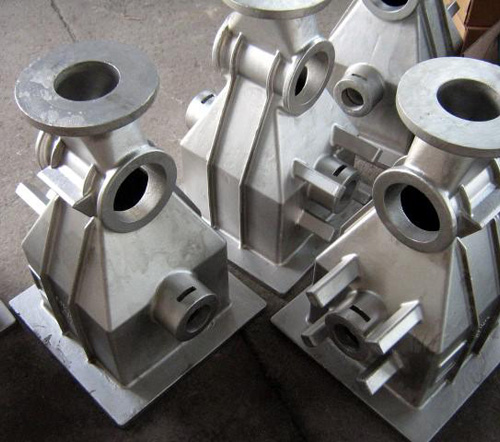

Lost wax casting is a fragmented and patience-testing process. A significant amount of detailing and precision is required to achieve a high-quality final product. The Lost Wax Casting Wholesale team at Solid Casting is known to be one of the most experienced Lost Wax Casting Suppliers in the country. A series of steps are to be followed by the professionals to present a customized lost wax cast product. The wax model is shaped and melted metal is poured on top to reflect the shape. Once the metal is set into formation the wax model is melted and extracted. The Solid Casting foundry is fully equipped with innovative and productive machinery for the efficient production of mechanical tools.

- Process

SOLIDCASTING supplies Lost wax castings using water glass and silica sol casting .

- Equipment

125-2000 kg medium frequency induction furnaces. Wax injection wax welding dipping sand-coating shell making dewaxing pouring decoating cutting and cleaning/shot blasting equipment. Heat treatment facilities for normalizing annealing quenching and tempering. Medium–frequency stove fore and hind temperature Meters chemical analyze and mechanical test instruments Meters chemical analyze and mechanical test instruments